RCA

Root Cause Analysis –

For exactly what reason did something happen?

For exactly what reason did something happen?

Did you also experience this before? Actually, everyone thought they had fixed the error. And yet similar undesirable things keep happening in your organization. Even your colleagues from Quality Management cannot come up with a solution. What to do?

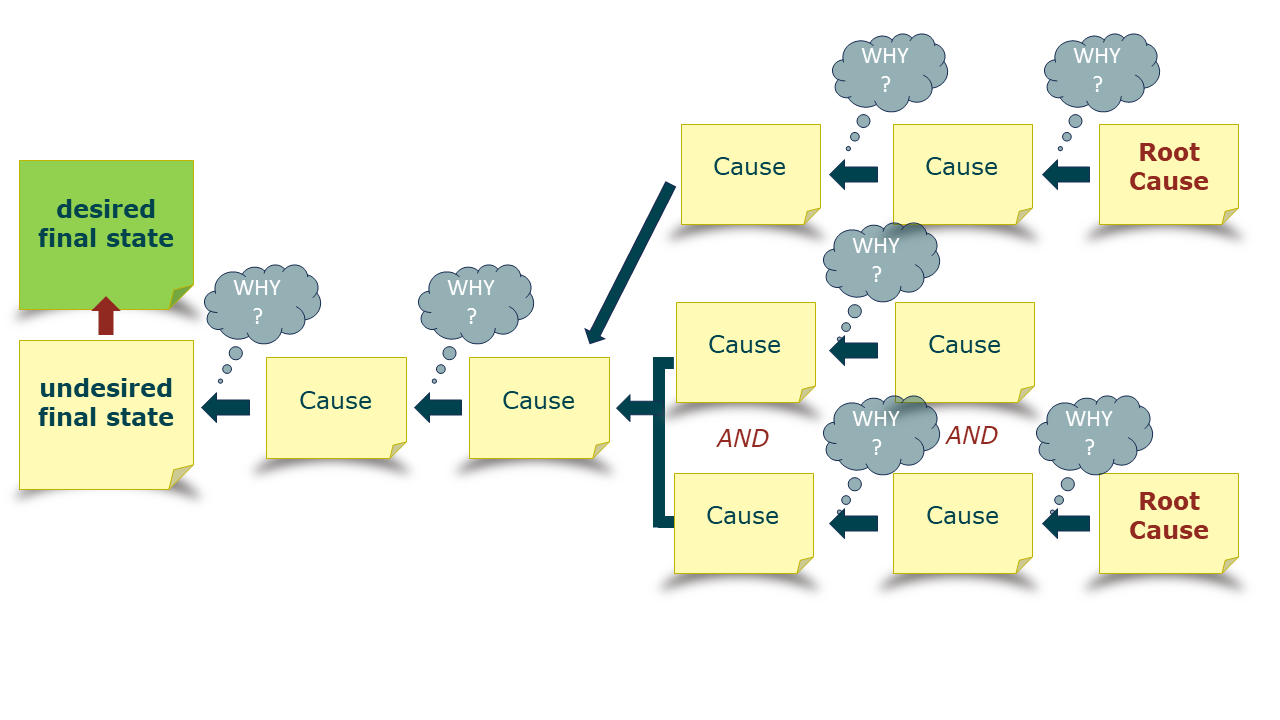

A root cause analysis can help here. It is utilized to get to the actual root of the error or the final state. Error models (e.g. Swiss Cheese Model according to J. Reason) assume that every error has several precursors that should be mitigated and absorbed by different safety barriers. Often the error process is stopped by one of these safety barriers and does not come to light (a so-called latent condition). However, it can happen that an error process can penetrate all security barriers undetected and ultimately becomes apparent. This is then referred to as an active error.

Deeper process understanding

And now? Just fix the error? This is what tends to happen in many organizations. Only the safety barrier immediately preceding the error or final state is addressed and a solution is implemented. This is convenient and quick to do. However, this approach is very likely to result in similar situations occurring again and again because the underlying root cause is still present.

This is exactly where Root Cause Analysis, or RCA for short, comes into play. Instead of superficially looking for solutions, the entire process is examined and the deeper causes are looked for. This has several advantages: On the one hand, the entire process is made more robust and you can often find solutions that are relatively easy to implement. Because they are located at a very early stage of the error process – where the effects are not yet serious. On the other hand, this method can also be used to discover the latent conditions (the part of the iceberg that cannot be seen). These have a much greater threat potential than active errors. Because they lie dormant and undetected in the organization and will reveal their potential for error at the worst possible moment. RCA helps on the path from Safety I to Safety II, i.e. the path from reactive to proactive handling of errors and final states.

“WHY?” instead of “WHO?”

RCA offers a structured approach to analysing processes, assigning causes and implementing solutions. Using the 5 Why-Method, reasons for the results of a process are gradually searched for in an RCA matrix. The focus is always on the process, i.e. on the WHY. The fingerpointing that is otherwise often encountered is replaced by an objective, fact-based approach. This is the only way to develop sustainable, transparent and effective solutions. RCA can do much more: Used as a tool to illuminate positive process results, RCA helps to strengthen employees’ behaviour. RCA helps to promote a positive, fair corporate culture (Just Culture / Psychological Safety) and thus raises resilience throughout the organization to a higher level.